Acoustical Plaster

Acoustic Plaster

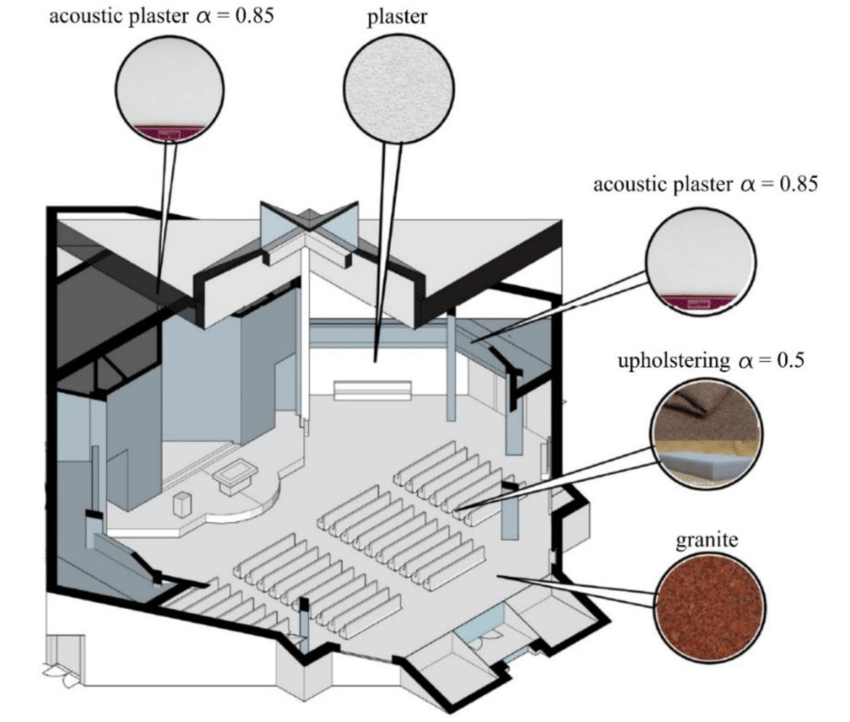

Acoustic plaster is a visually appealing solution due to its seamless, smooth application, offering an advantage over panels that may show visible joints. While some acoustic plasters include aggregates, higher-quality systems incorporate fibers for enhanced performance. These plasters are typically applied in thicknesses of 16mm, 20mm, or 25mm.

Acoustic plaster consists of a base layer made from absorptive substrate panels, commonly mineral wool or non-combustible inorganic blow-glass granulate. A first finishing layer is applied over these panels, creating an initial system of sound attenuation once dried. For greater sound attenuation, a second finishing layer can be added. If the density of the second layer is less than or equal to the first, it will provide enhanced sound absorption, offering flexibility in adjusting the acoustic properties of a space.

Acoustic plasters can substantially reduce sound reverberation, with a Noise Reduction Coefficient (NRC) ranging between 0.5 and 1.0. However, they may be more susceptible to physical stress and humidity, requiring care in certain environments.

While acoustic plaster delivers excellent acoustic performance, it demands high levels of craftsmanship for optimal results. Various mounting styles also influence the system’s overall acoustic efficiency and absorption coefficients. Acoustic plaster is commonly used in spaces that require superior acoustic qualities, such as auditoriums and libraries.

Assembly and Installation Overview

- Install the drywall grid system.

- Attach the acoustic panels to the grid using construction adhesive and drywall screws.

- Finish and tape the joints, covering screw holes.

- Spray-apply a fine texture finish to complete the surface.

This method ensures a durable, high-performance acoustic system suitable for various applications.